Capabilities

From the world’s best brands in our store.

Capabilities

We are our experts in most of the most specialized processes in the glass industry.

KILN CASTING

By heating glass above or inside a refractory mold until it flows to fill the void, the technique known as kiln casting creates a glass item in a kiln. Making the mold is one of the most difficult aspects of kiln casting. Molds that are open-faced or closed/semi-closed can both be utilized in kiln casting. A reverse-relief, bas-relief pâte de Verre, thick-block, or box casting will be the final product when employing an open-faced mold. You may create complete sculptures using closed or partially closed molds.

SANDING

One of the oldest valued methods for producing decorations with exceptional beauty and impact is sandblasted glass. Its foundation is corundum glazing, which has long since taken the role of sand. Sanding is the act of immersing the glass in acidic liquid (or smearing an acidic paste). The flat surface of excellent frosted glass is obscured by scattering from crystallization. If the surface is uneven, then glass has experienced acid erosion. perhaps only a portion of the crystal has fully developed. This technology is difficult and the glass quality is not easy to control.

MOLDING

A glass gob is compressed in a single operation into the shape of a completed lens during the glass molding process, which uses hot compression forming. Both existing and custom finishes have been exquisitely blended into designs for historic and modern rooms. Our ability to create the most imaginative interior decorating concepts for any building project is made possible by this technique. At Glassify, most cast glass is made by melting the glass in a kiln and then pouring it into a plaster mold or a sand mold. The surface of the glass may now be etched with incredibly detailed designs that can be generated using this technology.

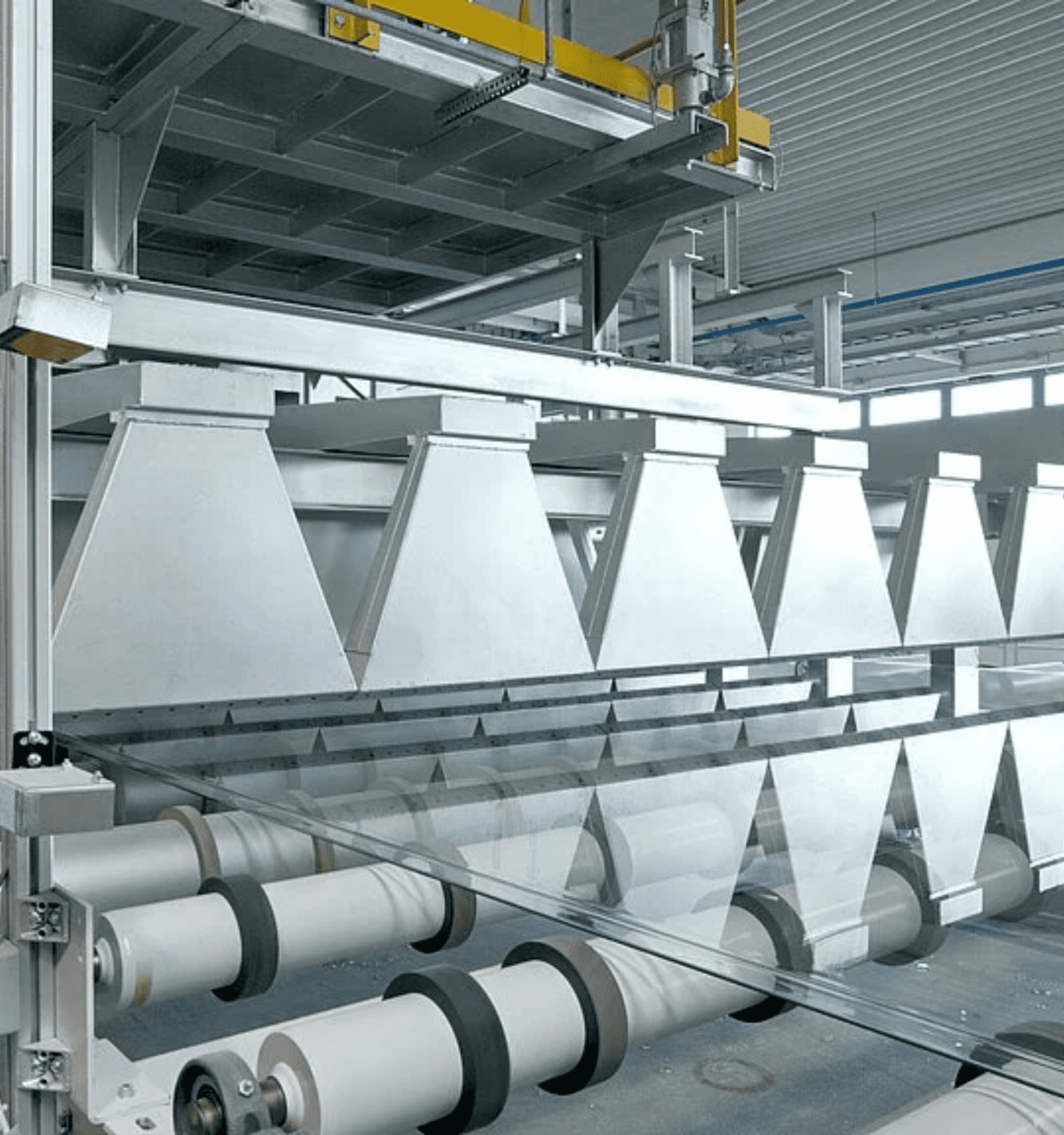

ANNEALING

After being produced, heated glass items are progressively cooled down during the annealing process to remove any remaining internal tensions from the manufacturing process. Annealing may be a necessary part of the manufacturing process, particularly for smaller, simpler things, but for bigger or more complicated goods, it sometimes necessitates a specific annealing procedure in a temperature-controlled kiln known as a lehr. The use of this procedure gives the glass one of its most distinguishing physical characteristics, how it responds to temperature change.

TEMPERING

In order to enhance its strength in comparison to regular or conventional glass, glass undergoes a thermally controlled toughening process when it is tempered. The process of tempering compresses the glass’s outside surfaces while tensing its inside surfaces. Due to the tension, instead of shattering into sharp pieces that may cause damage, the glass breaks into tiny granular bits. Unheated annealed glass will shatter into jagged shards rather than the “safety” pieces or dice that other types of glass do.For uses like automobile windshields, shower doors, glass tables and doors, and more, tempered glass, which is regarded as safety glass, is employed.

LAMINATING

The concept of safety glass is expanded upon by laminated safety glass. Although highly safe, tempered glass can still break into loose fragments if it is cracked in any other way. These might be bothersome despite being boring. Those glass fragments are kept securely in place by laminated safety glass.Laminated glass is one of the safest types of glass. It is sturdy enough to be employed in several high-traffic locations where dependability and safety are crucial. When hit, laminated glass usually breaks in a circular, spider-web-like pattern rather than altogether.

INSULATING

Insulating glass is created by sandwiching a spacer between two or more plies of glass. Two plies of glass and one sealed air pocket are used to create the most typical insulating glass unit. This arrangement is often referred to as a dual pane or double pane insulating glass unit, however it is usually abbreviated as IGU or insulating glass. The foremost company for architectural insulating glass is Glassify.Insulating glass units are sealed at Glassify using silicone for both the main and secondary seals. Insulating units are made to withstand pressure and temperature expansion without being stressed, resist moisture penetration, maintain a gas-tight seal to prevent the leakage of any speciality gas fill, and avoid condensation.

HEAT STRENTENING

Glass that has been heat-strengthened cools more slowly than tempered glass, resulting in less compression strength. The strength of heat-strengthened glass is around two times that of annealed, or untreated, glass. Compared to tempered glass, heat-strengthened glass offers a superior surface quality because it is less likely to develop aesthetic flaws during the strengthening process. Information on ASTM C-1048-4 is available. With no requirement for edge compression, the surface compression for heat-strengthened glass must range from 3,500 to 7,500 psi. The minimum surface compression for fully tempered glass is 69 MPa (10,000 psi), while the minimum edge compression is 67 MPa (9,700 psi).

BLOWING

Since the first century B.C., people have shaped glass using a method called glass blowing. By using a blowpipe to inflate molten glass into a bubble (or parison), the glass-forming method known as “glassblowing” is used to create glass (or blow tube). Glass blowers, glassmiths, or gaffers are those who work with glass. A lampworker, who is also sometimes referred to as a glassblower or glassworker, works with glass on a smaller scale while using a torch, for example, to create precise scientific glassware from borosilicate glass.

DIGITAL PRINTING

Using cutting-edge digital glass printing technology, Glassify creates pieces of art that are printed directly into glass. Many different business and residential uses are possible for digital glass printing. Glassify assists artists, builders, interior designers, architects, and glass retailers in realizing their glass-based visions.Designs, patterns, solid colors, and logos may all be printed directly into glass using Glassify’s digital glass printing technology. Modern ceramic inks are used by our high-resolution 1440 dpi printer. You will receive help for your project’s project management from our in-house design team as well as graphic design assistance. For many different sectors, we work on projects of every size, from little to huge.